Printable X-ray detectors are on the horizon

Using materials typically associated with solar energy devices, researchers are paving the way for a future that includes printable X-ray detectors.

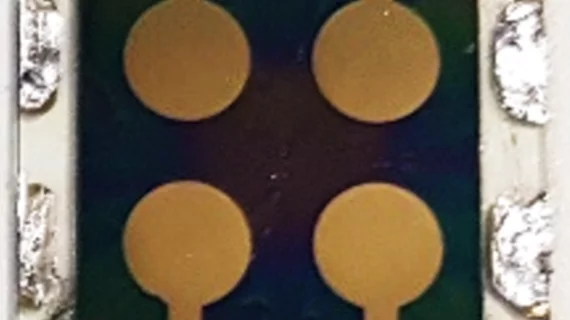

Researchers with Exciton Science are in the process of developing the technology thanks to their creative use of printable diodes made using perovskite thin films, which could offer numerous benefits in multiple imaging applications, according to experts involved in the work.

The team’s work was detailed recently in Advanced Materials.

“These perovskite-based detectors can provide rapid response times and offer high sensitivities to enable real-time detection and imaging for complex purposes, including disease diagnoses, detection of explosives and identifying food contamination,” first author of the new research Babar Shabbir, Senior Exciton Science Research Fellow, and colleagues explained.

One benefit of these new detectors is that they can operate at multiple energy levels, whereas traditional X-ray detectors typically operate at just two levels—hard or soft. In medical imaging there is often a need for detectors to be able to operate across both energy levels.

Conventional multi-energy detectors that are made with silicone and selenium are limited in their sensitivity and spatial resolution due to the thickness they require for X-ray attenuation. The team of researchers found that perovskite materials can offer a solution to this. When they are produced within a diode device, they can better manage the process of X-ray attenuation.

The team found that these detectors can operate in a significantly wider energy range (0.1 Kev into the 10s of KeV) than current multi-energy detectors and can efficiently attenuate both hard and soft X-rays.

Another benefit of perovskite detectors is their small size—they can be made as a thin film, which gives them the ability to be produced in multiple shapes and sizes to accommodate different devices. Professor Jacek Jasieniak, senior author on the paper and an Exciton Science Chief Investigator, suggested that these detectors also come with cost-savings.

“They should be cheaper to make, and could also involve modified film form factors, where you need inherent flexibility,” Jasieniak explained. “It opens up the field to a whole new set of questions about how to use these types of devices.”

To learn more about the new technology, click here.